Our experienced design and project teams are always able to adopt new industrial standards to integrate them into products to meet customer's requirements. We specialize in various types

Our experienced design and project teams are always able to adopt new industrial standards to integrate them into products to meet customer's requirements. We specialize in various types

Design & Assembly

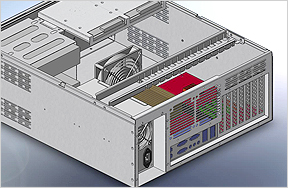

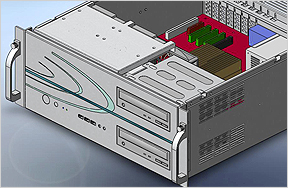

We can build from ground up to come up with a completely new products by taking verbal description concept , concept idea sketches, design CAD drawing (duplication/fabrication)

We can make changes to the products from our existing models to a certain degree as a cost driven compromise and lead time shorten.

The chassis can consist of metal work, cooling, size constrain, data backplane, input output access, LED in PCB/connector head with wires/cables

Design From Start To Finish

Our specialists have you covered from start to finish, including covering mechanical design, electrical design, and several other services for your custom project.

- From Concept to Completion

- Tooling Design & Manufacturing

- Customized Mechanical Products

- Plastic Molding & Injection

- Pressure Die Casting

- Rapid Prototyping

- Advanced Digital Prototyping

- Adherence to Safety Agency Policies & EMI Considerations during Design Process

- Agency & Regulatory Services Include:

UL, CSA, TUV, CE, FCC, NEBs, & MIL - Special Materials, Coating, & Finishing Design

- Product Packaging & Graphics Design

- Acoustics/Noise, Vibration, Thermal & Air FlowTesting

- Manufacturing Support Prototypes & Production

- Hard to find parts/components Sourcing assist

- international Support (with facilities in USA, Taiwan, China)

IStarUSA Engineers work closely with clients to create accurate and valid drawings of each OEM & ODM project.

We help you visualize your pre-production product using the latest, high-end 3D engineering software available.

- 3D Sample Drawings

2D & 3Dsamaple drawings are generated during the product Development Ph - 3D Renders

To give an even more realistic impression of what the product will look like, we also provide hyper-realistic 3D renders of each product. - We'll help you fine_tune your design to perfection before ordering the physical prototype.

Engineering

We materials such as aluminum intrusion, sheet metal in steel or in aluminum, plastic injection mold. Treatment such as, Perforation, cooling/thermal, precision, durability, rugged strength (quality), cutting, banding, stud pressing, welding, solder, filter, anti-vibration, add-on parts like acounstic noise reduction padding.

Motherboard Compatibility

IStarUSA can build you a chassis to match your motherboard specifications, most up-to-date m/b size we have put our hands on in the past and recrntly are:

| Form Factor | Max Size(in) | Max Size(mm) | |||

| ATX | 12 x 9.6 in | 305 x 244 mm | |||

| SSI CEB | 12 x 10.5 in | 305 x 267 mm | |||

| SSI EEB | 12 x 13 in | 305 x 330 mm | |||

| SSI MEB | 16.2 x 13 in | 411 x 330 mm | |||

| Micro-ATX | 9.6 x 9.6 in | 244 x 244 mm | |||

| Mini-ITX | 6.7 x 6.7 in | 170 x 170 mm | |||

| New Intel standard | 4 x 4 in | 102 x 102 mm |

Choose from redundant or singular power supply options. Redundancy can be customized to multiple levels to keep each unit running smoothly and without interruption.

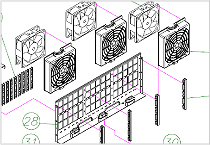

We carefully construct each unit to maximize air flow within each unit, thereby increasing thermal efficiency and data integrity.

- High quality, heat-dissipating materials such as Aluminum

- Active cooling

- Passive Heat-Sink add-on parts

- Hot-Swappable & easy swap Fans

- Internal & External Designs that minimize heat retention

- Audible and LED indicator warming devices & remote Alert Applications to prevent overheating

- Follow fluid dynamic to maximum air flow

Numerical Controlled Machine Technology(NCT) is one of the most cost-effective solutions for the production of complex, custom OEM & ODM solutions. These advantages include:

- Higher Productivity at smaller costs

- High level of accuracty and precision

- Easier to figure out material requirements

- Relatively to backtrack and make design adjustments

- Highly-efficient machining procedures

- Ability to store production & design details for future integration

- Optimizied production procedures to reduce manufacturing time therefore to reduce lead time for smaller run

- Produce higher quality products

- Simplified pre-production planning

- Reduction of product fabrication errors

A popular method for cutting materials in the industrial manufacturing process, IStarUSA utilizes Laser Cutting technology to create high-quality surface finishes for flat-sheet materials, including stainless steel and aluminum.

Hard Tooling is relatively more ideal solution for the mass production of custom OEM & ODM solutions, producing higher quality products in large quantity.

- Includes highly-customized die-casting process

- Utilized as a highly durable production method in such as metal staming

- Consistent quality precision

- Great for high-volume production, capable of producing thousands to millions of parts

Branding

Lorem ipsum dolor sit amet, consectetur adipiscingelit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enmin ad minim veniam, quis nostrud exercitation ullamco labors nisi ut aliquip ex ea commodo consequat. Duis aute irue dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in cuipa qui officia deserunt mollit anim id est laborum.

Logo & Labeling

Lorem ipsum dolor sit amet, consectetur adipiscingelit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enmin ad minim veniam, quis nostrud exercitation ullamco labors nisi ut aliquip ex ea commodo consequat. Duis aute irue dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in cuipa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscingelit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enmin ad minim veniam, quis nostrud exercitation ullamco labors nisi ut aliquip ex ea commodo consequat. Duis aute irue dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in cuipa qui officia deserunt mollit anim id est laborum.recmomended for medium - to large-volume orders.

- Matte Powder Coating

- Anodized Aluminum with Fine Brushing

- Injection Molding with Matte Finish

- Print on plastic, metal, and glass

Ideal for small-volume orders.

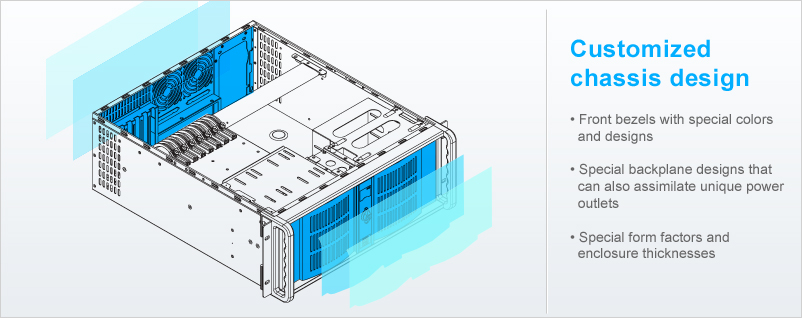

Bezels:The Front Door

Customizing the bezel door to any unit is key to creating brand awareness for any IT product line. At IStarUSA, we offer more than 25 years of trusted OEM & ODM experience to help you define this awareness at the enterprise level

|

The Beauty of Customization

| Choose from a multitude of styles, colors, and patterns made to order |

| Add your own logo or brand to the design |

| Satisfaction with a design that not only tells your customers who you are - get a design your customers will remember you by |

Building Your Solution

| Customized Bezel for Rackmount/Desktop Systems |

| Choose from Metal, Aluminum, or Pastic Materials |

| Differentiate yourself from the competition |

| Flexibility for all your custom branding needs |

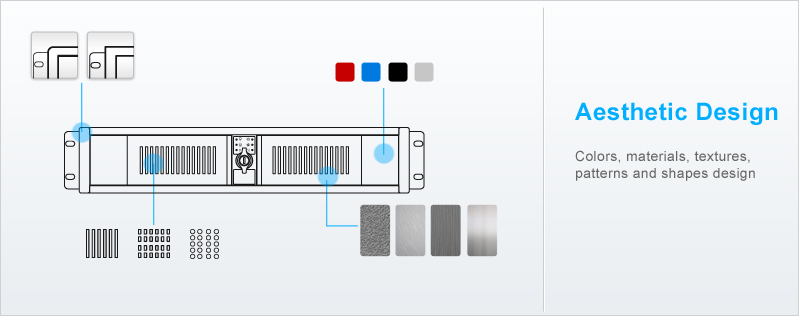

Materials & Styles

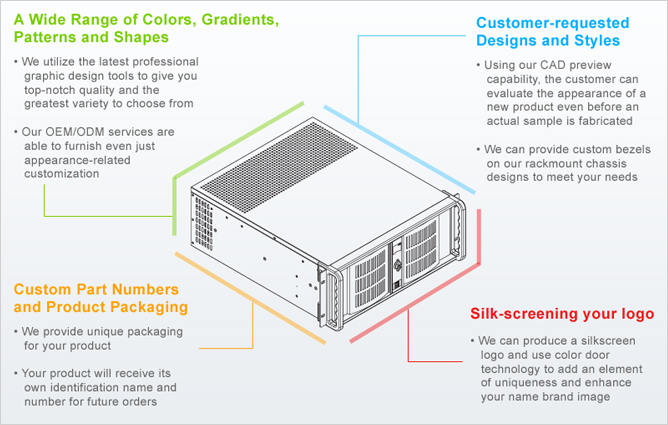

Often a unique styling with fine finish is treated as another kind of branding. It is like you can tell a product is an Apple, a BMW, a Burberry, a Hummer by just looking at the style, and further more you can easily tell by the logo without the name printed!!

Styling cue, coloring texture, patterning, mesh and grill, perforation, paint.

You Choice of materials, Colors, & Styles

Along with custom labeling options, IStarUSA can customize your unit to reflect the materials, colors, and styles that identify your specific brand.

Branding is more than just a logo on a faceplate, it is that overall feel and look that is not compromised!

In order to make your product unique, we offer an varierty of tools and capabilities for you:

Choose Your Own Materials

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brand with Your Own specific Colors with Paints & Powder Coating

Mix, match, and customize not only materials, but also your colors to showcase your specific brand. Base on the Pantone(PMS) color you provide. We can make the painting/coding or anodizing procrss to match the colors.

|

recmomended for medium - to large-volume orders.

- Aluminum Casting & Extrusion

- Brazing

Removing material from metallic strips or blank areas. - Embossing

Raised, sunken, or relief designs & patterns. - Metal Blanking

Punching, cutting, or shearing stock metal materials, usually in preparation for additional design processe - Metal Stamping

Forming strip or sheet metals using extreme pressure. - Notching

Removing material from metallic strips or blank areas. - Press Braking

Bending, blanking, corrugating, curling, notching, perforating, piercing, or punching metals. - Punching

Forming metal components. - Roll Forming

Creating shapes and contours. - Shearing

Cutting metals. - Welding

Joining metals, including grinding, polishing, filling voids, preparation and priming for painting or other designs processes.